The Service Department maintains, repairs, and recertifies all safety critical equipment offered by IRP Fire & Safety Limited. Our commitment is to provide a quality service that meets industry practices, manufacture recommendations together with international codes and standards. The service team is comprised of dedicated competent professionals that is manufacture trained with over thirty five years industry experience. We can be called upon 24/7 to respond to emergencies that arise during your operation. Our on time customer support and problem solution skills are unrivalled in the industry, giving you our customers peace of mind.

Hydrostatic Testing of Fire Extinguishers

- All cylinders are tested using our Automated Hydrostatic Water Jacket Cylinder Test System

- Cylinders are tested to meet DOT requirements.

- IRP technicians are Hazmat trained to requalify cylinders under U.S. Department of Transport title 49 ƥ 172 subpart H

- Hose Inspected in accordance with NFPA 10 2013 subsection 7.6

Inspection and Recertification of Fire Extinguishers

- Shall be done in accordance to NFPA 10 Chapter 7 in conjunction with the OEM Manual to meet industrial standards

- Extinguishers are inspected to ensure it is free of defects and is fit for service

- All extinguishers are properly labelled and tagged marking inspection date and next recertification date

- On Site or at our Facility

Service & Recharge of Fire Extinguishers

- Shall be done in accordance to NFPA 10 2013 Standards Chapter 7 and shall be carried out only by trained and competent personnel utilizing OEM service parts

- Technicians are trained with over twenty-five (25) years service experience

- Quick turn around for repairs and recharging of extinguishers

Hydrostatic Testing of Suppression Cylinder

- All Suppression cylinders are low pressure tested to meet DOT requirements and Guidelines by NFPA 17A Standard for Wet Chemical Extinguishing Systems

- IRP technicians are Hazmat trained to requalify cylinders under U.S. Department of Transport title 49 ƥ 172 subpart H

Recharge of Suppression Cylinder

- Refilling and Recertification of cylinders shall be done in accordance with OEM recommendations & NFPA 17A Standard for Wet Chemical Extinguishing Systems

- All cylinders are cleaned and inspected internally for deffects prior to refilling

- All cylinders are properly labelled and tagged marking inspection date and next recertification date

Inspection and Recertification of Kitchen Suppression Cylinder

- Inspection of cylinders shall be done in accordance with OEM recommendations & NFPA 17A Standard for Wet Chemical Extinguishing Systems

- All cylinders are cleaned during inspection to be free of grease and grime

- Recommended at least every 6 months

Degreasing Kitchen Suppression System Hood

- Degreasing are done by fully competent and experience technicians

- Care is taken to protect clients equipment and surrounding areas prior to degreasing

- Recommended at least every 6 months

Inspection & Recertification of Clean Agent Suppression Systems

- Fire Suppression Systems are serviced and tested in accordance with NFPA 2001 Standard on Clean Agent Fire Extinguishing Systems

Refill of Clean Agent Suppression Cylinders

- Refilling and Recertification of cylinders shall be done in accordance with OEM recommendations & NFPA 2001 Standard on Clean Agent Fire Extinguishing Systems.

Hyrdostatic Testing of Clean Agent Suppression Cylinders

- All Suppression cylinders are low pressure tested to meet DOT requirements and Guidelines by NFPA 2001 Standard on Clean Agent Fire Extinguishing Systems

- IRP technicians are Hazmat trained to requalify cylinders under U.S. Department of Transport title 49 ƥ 172 subpart H

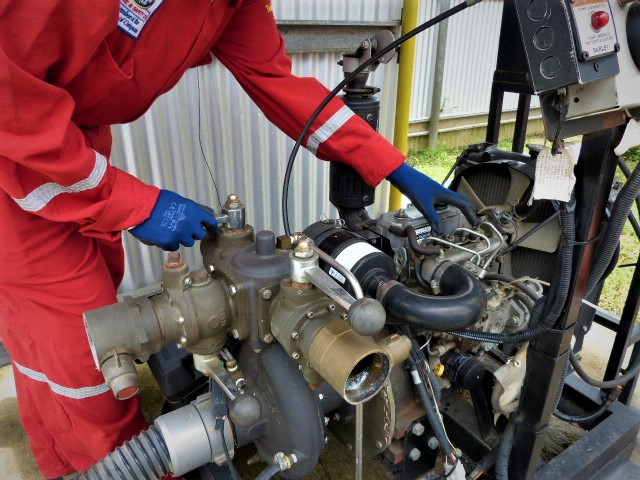

TRIMAX Compressed Air Foam (CAF) Systems

- Commissioning will include inspection, preparation for testing and 10 second discharge. Refilling of system after testing is included (Less consumables)

- It shall be done as per OEM recommendations as well as NFPA 10 2013, NFPA 25 and NFPA 1962

- Inspection of Trimax is done as per OEM recomendations as well as NFPA 10 2013, NFPA 25 and NFPA 1962

- Recommended Annually

Recertification of Components

Inspection & Recertification of Foam Carts

- It shall be done as per OEM recomendations as well as NFPA 10 2013, NFPA 25 and NFPA 1962

Installation of Fire Hose Reels

- Fire hoses shall be installed following the guidelines as per NFPA 1962 Standard for the Care, Use, Inspection, Service Testing, and Replacement of Fire Hose, Couplings, Nozzles, and Fire Hose Appliances, and BS-en-617 standards

Service & Repair Fire Hose

- Fire hoses shall be repaired using OEM guidelines along with NFPA 1962 Standard for the Care, Use, Inspection, Service Testing, and Replacement of Fire Hose, Couplings, Nozzles, and Fire Hose Appliances

Pressure Testing of Fire Hose

- Pressure testing of fire hoses shall be carried out in accordance with NFPA 1962 Standard for the Care, Use, Inspection, Service Testing, and Replacement of Fire Hose, Couplings, Nozzles, and Fire Hose Appliances by a trained Service Technician

- Pressure testing is done using certified hose testing equipment

- Each hose test is graphical recorded for the duration of the test

- Onsite or at our facility

Inspection of Building System Hose Reels

- Inspection of Building System Hose Reels in accordance with EN 671-3:2009 (E)

- Inspection of Industrial Systems Hose Reels in accordance with NFPA requirements

Inspection & Recertification

- Inspection of Fire Pumps should be done in accordance with NFPA 25 Chapter 8

- For on-site services there is a charge for Pump Testing Equipment.

- Testing Misc. consumables are also an adder.

Inspection & Recertification of MSA SCBA and Airline Respirators

SCBA & Respirator Facepiece Fit Testing

- Test using Porta Count Pro respirator fit tester, in accordance with OSHA’S

RESPIRATORY PROTECTION STANDARD 29 CFR 1910.134

SCBA & Respirator Facepiece Sanitizing

- Sanitization entails cleaning with MSA germicidal wipes.

- Additional Cleaning available using an Ultrasonic Bath

Hydrostatic Testing of SCBA Breathing Air Cylinders.

- All cylinders are tested using our Automated Hydrostatic Water Jacket Cylinder Test System. Cylinders are tested to meet DOT requirements.

- IRP technicians are Hazmat trained to requalify cylinders under U.S. Department of Transport title 49 ƥ 172 subpart H

Hydrostatic Testing of Supplied Air Cylinders

- All cylinders are tested using our Automated Hydrostatic Water Jacket Cylinder Test System. Cylinders are tested to meet DOT requirements.

- IRP technicians are Hazmat trained to requalify cylinders under U.S. Department of Transport title 49 ƥ 172 subpart H

Refilling of SCBA Breathing Air cylinder

- Cylinders are filled to Grade D specifications as outlined by NFPA 1989 Standard on Breathing Air Quality for Emergency Services Respiratory Protection

Refilling of Supplied Air Cylinders

- Cylinders are filled to Grade D specifications as outlined by NFPA 1989 Standard on Breathing Air Quality for Emergency Services Respiratory Protection

- IRP’s Compressors are tested for air quality on a quarterly bases as required by NFPA 1989

Service & Repair of Nitrogen and Breathing Air Cylinders

- Cylinders valves are evaluated, serviced and reapired for leaks and damage valve handles

- Any type of Painting requires a trained and competent person and shall be done in accordance with Manufacturers requirements or that of the Clients Offshore Coating Specs.

Service & Calibration of Portable Gas Detection Instruments

- Calibration of Portable Gas Detection Instruments by Manufactured certified Technicians

- Instruments are calibrated in accordance to Manufacture specifications and recommendations outlined by both International Safety Equipment Association (ISEA) and Occupational Safety and Health Administration (OSHA).

Sanitization of Portable Gas Detection Instruments

- Instruments are cleaned in accordance to manufacture guidance to prevent, control, and manage contact with the Coronavirus (COVID-19)

Preventative Maintainance of Fixed Gas Detection Systems

- Service & Calibration by Certified Manufacturers Technicians

- Recommended Quarterly

Preventative Maintainance of Fixed Flame Detection Systems

- Preventative Maintainance of Fixed Flame Detection Systems

- Cost of Service and Testing depends on the quantity of detectors on system.

- Instruments are serviced and tested in accordance to Manufacture specifications.

Preventative Maintainance of Fire Detection & Suppression Systems

- Fire Alarms Systems are serviced and tested in accordance with NFPA 70 & NPFA 72

- Fire Detection and Suppression are serviced and tested in accordance with NFPA 2001

Inspection Testing of Emergency Lighting / Exit Lighting

- Inspection and Testing of Emergency Lighting / Exit Lighting

Inspection of Fall Protection Equipment

- Fall Arrest equipment in inspected to ANSI Z359.2-2007 General Industry Best Practice Standard Minimum Requirements for a Comprehensive Managed Fall Protection Program & MSA Competent Person Fall Protection Equipment Inspection Manual, 2014

- Tripod systems is inspected as per ANSI Z359.14-2012 Safety Requirements for Self-Retracting Devices for personal fall Arrest and Rescue Systems

About

Fire Protection Systems are designed and installed to protect both personnel and property, including high value assets, from damage in the event of a fire. These systems could be costly to install but once properly maintained and tested, will deliver countless years of dependable service.

IRP’s competent Engineers and Technicians are factory and supplier trained and are experienced in carrying out testing and maintenance in accordance with the relevant OEM manuals and NFPA Standards. They are equipped with the necessary tools, software, and equipment to successfully carry out the testing on the full range of Fire Protection Systems available and have working relationships with foreign partners specializing in the related system.

Utilizing design information for the system and/or as-built data, IRP’s Team will record the necessary data during the testing, conduct detailed analysis of the results and provide the Client with a comprehensive report, including recommendations to correct any issues and improve the operation of the system.

Deluge System Testing

- NFPA 25- Standard for the Inspection, Testing and Maintenance of Water Based Fire Protection Systems.

- Inspection and Testing of the complete deluge system including:

- Water delivery components- pipes, pipe fittings, fire departmentconnections, sprinkler, etc.

- Alarm and supervisory components.

- Control valves, regulating devices, gauges, etc.

- Hangers and seismic braces inspection at floor level.

Fire Water Pump Flow Testing

- NFPA 25- Standard for the Inspection, Testing and Maintenance of Water-Based Fire Protection Systems.

- Inspection and Testing of the Fire Water Pump.

Hydrant, Monitor and Ring Main Testing

- NFPA 25- Standard for the Inspection, Testing and Maintenance of Water-Based

- Fire Protection Systems.

- Inspection and Testing of the complete Hydrant and Ring Main system including:

- Inspection of hydrant barrel, monitor nozzle, hose houses.

- Water delivery components- pipe, fittings, strainers, fire department connection, etc.

- Valves, gauges, identification tags, etc.

- Structural components- thrust blocks, tie rods, etc.

Foam Concentrate & Proportioning

- NFPA 25- Standard for the Inspection, Testing and Maintenance of Water-Based Fire Protection Systems.

- NFPA 11 – Standard for Low-, Medium-, and High-Expansion Foam.

Services include:

- Testing of foam proportioning system.

- Testing of foam concentrate.

- All foam analysis conducted by a certified lab.

- Capable of testing any brand of foam product.

- Capable of conducting both refractometer and conductivity meter testing methods.

Room Integrity, Air Tightness and Safe Shelter Testing

- NFPA 2001 – Standard on Clean Agent Fire Extinguishing Systems.

- ISO 14520 – Gaseous fire-extinguishing systems — Physical properties and system design.

- BS EN 15004 – Fixed firefighting systems. Gas extinguishing systems. Design, installation, and maintenance.

- IRP’s Technician are the only Retrotec Certified testers in the Caribbean with levels 1-3 Enclosure Integrity certification. Services includes:

- Air tightness test, Room Integrity and Duct Leakage test.

- The very latest in testing technology will provide thorough informative assessments concerning potential areas of leakage, advice and recommendations on protection and solution.

- Full retention reports.

Fire Truck Testing

BS EN 1846-3:2013 Firefighting and rescue service vehicles. Permanently installed equipment. Safety and performance

IRP’s competent Technicians are trained and are experienced in carrying out testing and maintenance in accordance with the relevant OEM manuals and NFPA Standards. They are equipped with the necessary tools, software, and equipment to successfully carry out the testing on the full range of Fire Truck Systems available and have working relationships with foreign partners specializing in the related system.

Services includes:

Inspection of Lights, Sirens/Horns, Operators Panel, Engine, Body, Hoses, Monitor, Breathing Apparatus, Extinguishers, etc

Fire Pump Test as per manufacturer specification

Full retention reports.

About

IRP’s TAR services offer a range of packaged solutions to meet the needs of your Turnaround. Our onsite management of the equipment supported by our experience ensures every device is fit for use each day.  The onsite TAR team conducts relevant inspections, testing and repairs prior to equipment being issued for use ensuring the TAR fleet of equipment is not reduced during this crucial period. Our equipment management service would complement the overall objective of the TAR providing quality work, reducing cost, and saving you time so you can focus on other critical operations during this time.

The onsite TAR team conducts relevant inspections, testing and repairs prior to equipment being issued for use ensuring the TAR fleet of equipment is not reduced during this crucial period. Our equipment management service would complement the overall objective of the TAR providing quality work, reducing cost, and saving you time so you can focus on other critical operations during this time.

Each package can be tailored by selection to fit every stage of your operation during the Turnaround. Bundles can be assembled comprising equipment from each package, all managed and controlled by IRP’s TAR onsite team to maximise your time, minimise your cost and provide efficiency to progress your jobs.

INSTRUMENTS PACKAGE

Option 1 – Altair 4XR Diffusion

Option 2 – Altair 5X Pump

Option 3 – Altair io360 Area Monitor

* Each instrument will be bump tested prior to going out on each shift

* All equipment is inspected and sanitized after each shift and is prep for the incoming shift

* Site training is conducted and recorded with end user before start of turnaround (Upon client’s request)

RESPIRATORY PACKAGE

Option 1 – PremAire Cadet Escape 5 minutes

Option 2 – PremAire Cadet Escape 10 minutes

Option 3 – Industrial Airline cart 2-60 Min cylinders

Option 4 – Airline cart 2-300 cu.ft. cylinders

Option 5 – SCBA 30 minutes

Option 6 – SCBA 60 minutes

Option 7 – Air Purifying Respirator (APR)

*All equipment is inspected and tested after each use and is made ready for next issue

BREATHING AIR COMPRESSOR PACKAGE

Mobile Compressor – Bauer Mobile Air Compressor, certified Grade D Quality air for supplied breathing air system

* Reduces time experienced by having to fill the cylinders off-site

* Reduces the need for having large quantities of stand by cylinders of breathing air

*Compressor is tested for air quality on a quarterly bases as required by NFPA 1989. Cylinders are filled to Grade D specifications as outlined by NFPA 1989 Standard on Breathing Air Quality for Emergency Services Respiratory Protection.

About

IRP’s Rental services provides the industry’s best safety equipment that your job demands for affordable daily, weekly, and monthly rates and long-term projects. Our rentals will save you the initial capital investment, eliminate cost of ownership, and the storage cost when not in use.

The safety equipment on the rental fleet are portable gas detectors and respiratory protection and coming soon fall arrest systems. All equipment can be prepared and delivered within a 24-hour period for those unplanned emergency work.

PORTABLE GAS DETECTOR

Our gas detection instruments carry the standard four (4) gases LEL, O2, CO and H2S. We have three types of instruments on the rental fleet which can vary depending on the nature of your operation. Pumped instruments for safety checks, diffusion instruments for personal monitoring and area monitors for continuous operations.

Option 1 – Four (4) Gas Diffusion Instrument

Altair 4X / 4XR GID, LEL, O2, H2S, CO, North American Power Supply, Glow in the Dark Case CO,LEL (0-100% Pentane), O2 (0-30% 4X ONLY), Duo Tox (CO 0-2000 ppm, H2S 0-200 ppm) CSA/ETL approval label. MSA P/N A-ALT4:-X-L-2-A-N-C-0-0-G-0

Option 2 – Four (4) Gas Pump Instrument

Altair 5X, Configured, Color Display, Sensor #1: LEL 0-100% Pentane, Sensor #2: Oxygen 0-30%m Sensor #3 (Exotic): None, Sensor #4: CO/H2S: 0-1999ppm & 0-200ppm, Advanced Sensor: None, Packaging: Red Economy, Approval Label: CSA/UL, Sampling Probe Kit Non React. MSA P/N A-ALTX5X-B-L-K-0-1-0-R-C-0-1-0

Option 3 – Four (4) Gas Area Monitor

Altair io360, Methane 0-100% LEL, 5.0 VOL%, O2 0-30%, 0-1999 PPM CO, 0-200 PPM H2S, 915 MHz (NORTH AMERICA), UL (US) Listed. MSA P/N A-ALTIO360L1ANNB01

Option 4 – Calibration Test System

Galaxy Automated Test system, c/w test stand and cylinder holder, Automated record keeping and calibration system for MSA portable gas detection instruments. System is stand-alone, requiring no computer, controller, or network interface. All gas tubing and communication paths are pre-connected.

BREATHING APPARATUS

Our top-quality respiratory protection fleet is equipped with Self-contained breathing apparatus (SCBA)

both 30-minute and 60-minute sets, Low- and High-pressure Airline carts, Escape sets and Air purifying respirators.

Option 1 – PremAire Cadet Escape 5 minutes

PremAire Cadet, MSA 5-min Carbon Cylinder, Ultra Elite Hycar Med. Ultra Elite Medium Nose Cup, Shoulder Pad, Nylon Carrying Bag, Firehawk PTC Solid Regulator, Rubber Head Harness, QD Foster SST, AL Respirator, c/w Hardcase.

Option 2 – PremAire Cadet Escape 10 minutes

PremAire Cadet, MSA 10-min Carbon Cylinder, Ultra Elite Hycar Med. Ultra Elite Medium Nose Cup, Shoulder Pad, Nylon Carrying Bag, Firehawk PTC Solid Regulator, Rubber Head Harness, QD Foster SST, AL Respirator, c/w Hardcase.

Option 3 – Industrial Airline cart 2-60 Min cylinders

Cart, Wheeled Portable (RENTAL), Industrial, AL Respirator, Equipped with Foster Steel Quick Disconnect fiitings, Two Sets double-cylinder straps, Airline-hose rack and adjustable pull handle Pressure regulator, Low-pressure cylinder alarm whistle, 125psig relief valve c/w Cylinder, MSA Stealth Custom 4500 MMR 60min. Green H-60 SCBA

Option 4 – Airline cart 2-300 cu.ft. cylinders

Cart, Breathing Air (RENTAL), 4 Port Manifold, 2 x 300, 2200 psig Cylinder, SS Flex Air-Line, SS CGA Nipple & Nut, 346, Audilarm, Regulator, 300 psi and 3000 psi Gauge, Galvanized material, painted for industrial environments, c/w cover, (kit) IRP.

Option 5 – Self-contained Breathing Apparatus (SCBA) 30 minutes

MMR, (RENTAL), Ulite HUD Fire Hawk STC Grey 2216psig, 30min.Stealth Cylinder, Air Double Pull Carrier, UElite Silicone Facepiece (HUD) Med. w/Lumbar Pad, Rubber Head Harness w/ Neck strap, Quick-Connect Slide, ICM TX w/o Heat Sensor, LCD Screen, Audible & Visual alarm, built in transmitter (w/ Hard Carrying Case)

Option 6 – Self-contained Breathing Apparatus (SCBA) 60 minutes

MMR, (RENTAL), Custom 4500 K-CMD14B00C12AD1 60 Min. Stealth Cylinder, UElite Facepiece (HUD) Med. Hycar w/Lumbar Pad, Speed-On Head Harness w/o Neck strap, Fire Hawk Regulator Quick Connect Slide, ICM TX w/o Heat Sensor (w/Hard Carrying Case)

Option 7 – Air Purifying Respirator (APR)

MSA Advantage Respirator c/w GME Cartridge and TAR Logo Pouch

Option 8 – Airline Hose

Hose, (RENTAL) MSA 50ft x 3/8″ Air-Line. Neoprene Black Univ. (c/w Fittings) Breathing Apparatus c/w Male Plug, Female Socket & Male Adapter

Option 9 – 30-minute Spare cylinder

Cylinder, (RENTAL) 2216psig, Stealth L-30min, MMR, Grey.

Option 9 – 60-minute Spare cylinder

Cylinder, (RENTAL) 4500psig, 60min Stealth H-30, Custom 4500 MMR SCBA

Option 10 – Airline 300 cu.ft. Spare cylinder Low pressure

Cylinder, Air 300 cu.ft. 2400psig., Chrome Yellow, AL Respirator, Breathing Air CGA 346 DOT# 3AA2400

Option 11 – Airline 300 cu.ft. Spare cylinder High pressure

Cylinder, Air 300 cu.ft. 4500psig., Chrome Yellow, AL Respirator, Breathing Air CGA 347 DOT# 3AA4500

*All equipment is inspected, tested, and issued for delivery with certificates

BREATHING AIR COMPRESSOR PACKAGE

Mobile Compressor – Bauer Mobile Air Compressor, certified Grade D Quality air for supplied breathing air system

* Reduces time experienced by having to fill the cylinders off-site

* Reduces the need for having large quantities of stand by cylinders of breathing air

*Compressor is tested for air quality on a quarterly bases as required by NFPA 1989. Cylinders are filled to Grade D specifications as outlined by NFPA 1989 Standard on Breathing Air Quality for Emergency Services Respiratory Protection.

FLEXIBLE HOSE ASSEMBLY INTEGRITY MANAGEMENT

1. Design and Specification of FHAs for application and environment

2. Assembly, Certification and Tagging of new and replacement FHAs

3. Consultation for Installation and Routing

4. Baseline inspection surveys and Risk-Based Inspections – inclusive of software and database access

5. FHA Spares Management

6. Technical FHA Training

7. Engineering Support for every FHA need

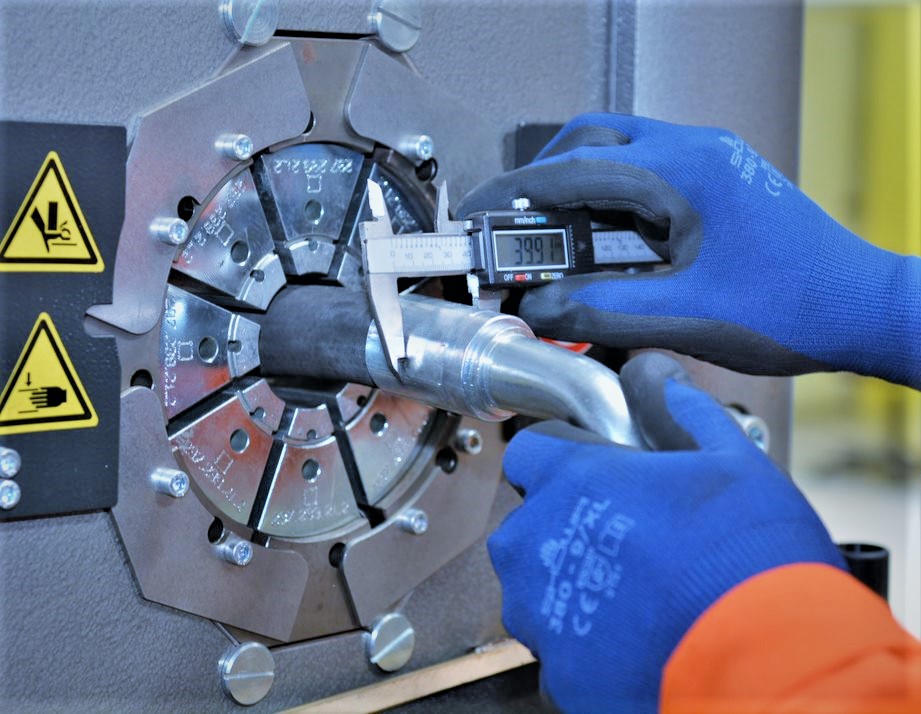

FLEXIBLE HOSE ASSEMBLY CERTIFICATION

Visual inspection

Hydrotesting to 1.5 times the working pressure and held for a minimum of 3 minutes

Tagging with UV protected paper tags or engraved stainless steel tags with relevant hose and test information

Provision of individual and batch Certificates

Onsite service can be provided where necessary. Equipment mobilization, rental and Technician day rates will apply

SPECIALIZED COUPLING SERVICE & RE-CERTIFICATION

Visual inspection

Repair and Service using spares kits

Hydrotesting to 1.5 times the working pressure and held for a minimum of 3 minutes

Tagging with engraved stainless steel tags with relevant information – optional

Provision of individual Service Checklists and Certificates

TECHNICAL TRAINING SERVICES

Customer specific and industry standard courses can be delivered at our Training Center or on any customer site. Chat with us about your training needs